Five years ago, I decided to try my hand at making chocolate. I had read that it takes a cacao tree five years to produce cacao, so five years ago I planted two trees. One tree is still not able to produce and I believe it is because it has been fighting against my banana trees to access sunlight, but the other tree is strong and now producing many pods of cacao, so I am now documenting my first efforts to make chocolate from tree to table.

Unripe cacao pods

To prepare myself, I studied many articles and watched many videos about the process. There are so many methods depending on the quantity of cacao seeds, the equipment you use, what type of chocolate you plan to produce. As a result, I put together a pick-and-choose plan, combining what I thought could produce a good chocolate using the whole pod, from seeds to pulp to husk because I wanted it to be as pure as possible while eliminating wasting the pulp and husk.

When the cacao first forms, it is a small, green pod which eventually grows to its full size and then changes to an orange color. Literature says when you shake the pod it isn’t ripe until you can hear the seeds rattle when you shake it. This was difficult, since the stem connecting it to the tree branch was short and the pod was growing in between two branches and basically stuck there. I did my best at deciding when to harvest it and am still not sure it was ripe enough. But there was no bad smell, so I don’t think it was overripe.

The next step was to open it without cutting the seeds, which I did.

One article said that the seeds taste a bit like pineapple. I ate one of the seeds and the article was correct – it did taste a bit like pineapple. The article also said that the juice is 14% sugar, and by distilling it down to form a highly concentrated syrup, “combined with the pulp and then taking sustainability to new levels, mixed with the dried husk, or endocarp” forms a very sweet cocoa gel which, when combined with the cacao beans, eliminates the need for refined sugar.

This is what I was hoping to accomplish.

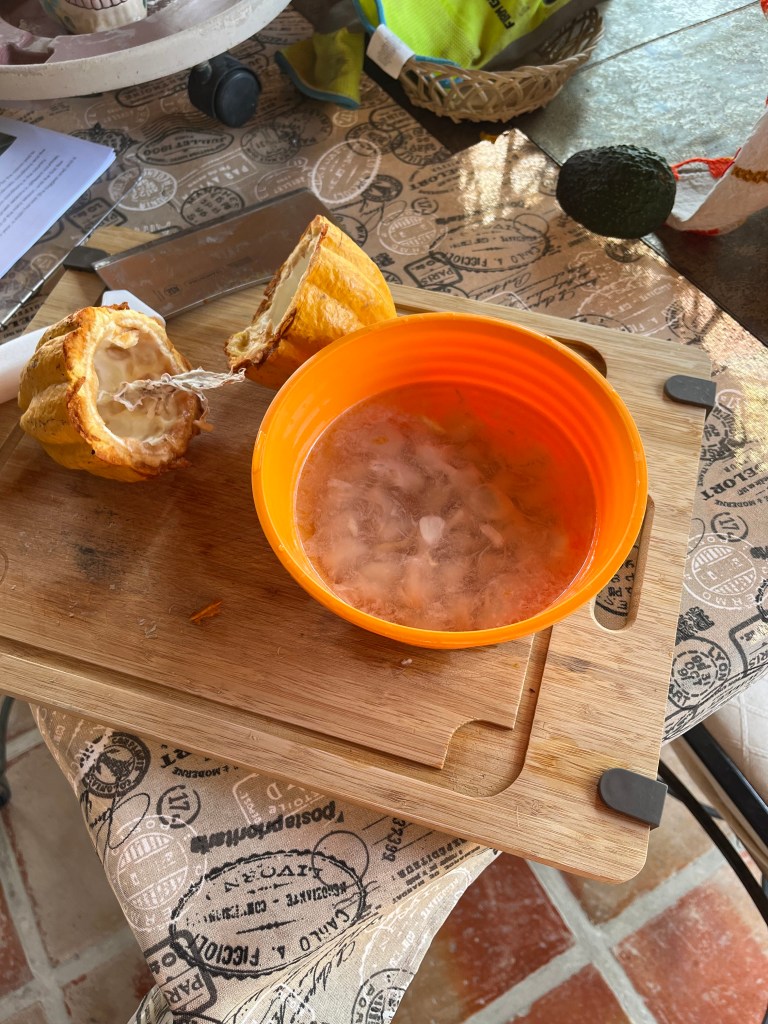

What I did was put the seeds in a small dish of water to wash off the thick white coating from the seeds. Then I cut the pulp from the husk and used a garlic press to try to extract the liquid from it. That didn’t work very well. In the end, I put the water with seed coating into a saucepan along with the pressed pulp and heated it on my stove. I didn’t end up with a gel, but I figured that the sugar content was still there, and I would add it to the finished product.

In the meantime, the literature said to dry the husk in an oven at 80ºC (176ºF) for 18 hours. I was not going to run my oven for 18 hours, and since it’s still very hot here, I put the pieces of husk on my outdoor drying table in the sun, covering them with plastic during the night to avoid the humidity. The literature also says to mill it to a fine powder once it is dry. Not having the equipment to do that, the husk ended up in my compost pile.

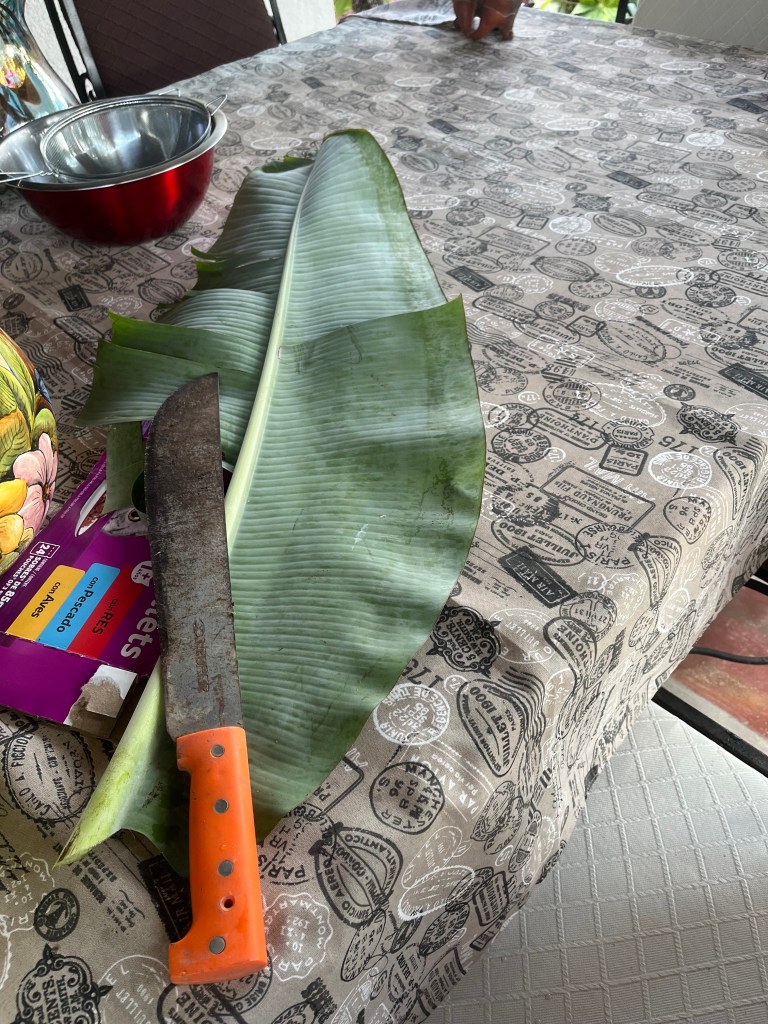

The seeds needed to be fermented as the next step. I read that some producers wrap them in banana leaves and leave them to ferment for 7 days, turning them daily. Since I grow banana trees I decided to use this method, and the seeds did turn brown, but I had no idea if and how much they had fermented. Because the seeds needed so much time to ferment, I froze the heated pulp mixture so it would not spoil.

Husk drying and seeds fermenting in banana leaves

Then it was time to roast the seeds. I put them on a cookie sheet and roasted them in the oven at 205ºC. (401ºF) for 6 minutes, then for 20 minutes at 132ºC (270ºF). They were then removed from the oven and left to cool for 15 minutes.

Cacao seeds ready to roast

Roasted cacao seeds with and without the shells

NOW they were starting to smell like chocolate.

I had already defrosted the frozen pulp mixture and was now ready to peel the roasted beans. Once peeled, I put them in my NutriBullet and they did end up as a thick paste. I added the pulp mixture and blenderized it some more.

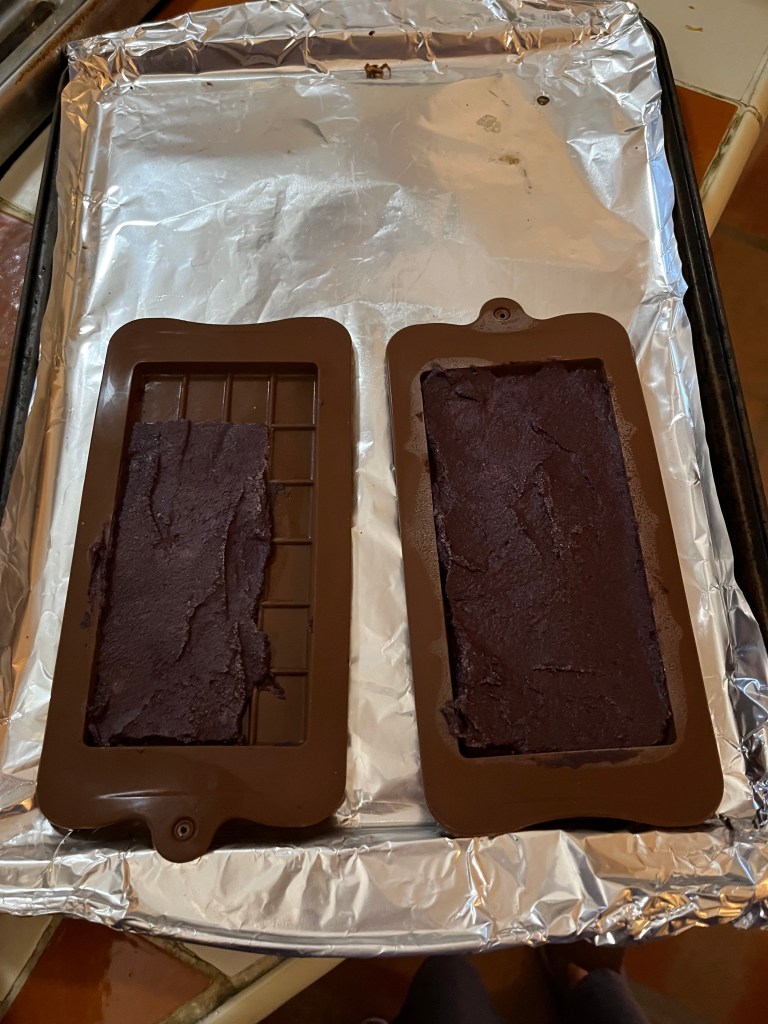

The taste of the resulting mixture was very bitter, so I ended up adding a few drops of almond extract and some refined sugar. It became slightly more tolerable. After that, I heated it in a double boiler to smooth out the mixture and spread it into the chocolate molds.

Heating the paste in the double boiler next to some defrosting pie dough

In the molds, ready to freeze

After freezing the chocolate came the moment of truth – how good or bad was my chocolate. Here is the video with the honest results:

I have to say it was a good learning experience. This was only from one cacao pod, and my tree is producing many more, so there will be many more trials until I get it right, if ever. It certainly won’t replace Hershey bars, Ghirardelli or my now favorite Carlos V Mexican chocolate, but it is a fun hobby. After years of living in a basement apartment, working nights and not seeing much sunlight, my garden is my little bit of Paradise and I enjoy every minute of being able to plant new species and work with many products which was impossible to do in New York.

And – most of the time I am not discouraged by failure. I remember decades ago when my son was in Cub Scouts. I volunteered to make brownies for an event. Knowing that many people were diabetic among the adults, I used saccharin instead of sugar. They were AWFUL – I’m guessing the correct word might be astringent. I apologized to everyone and admitted that they were, in fact, awful.

And finally, a thought that has crossed my mind many times as I learn to prepare meals from scratch. How long did it take various species of humans to convert certain natural plants, etc. into various forms of food – such as wheat into bread. Or poisonous plant life into edible forms. How many people died from eating raw casava, which contains cyanide, before someone decided – “Well, this root has killed so many of my kin, I wonder what would happen if I soaked it in water and then heated it and THEN WE ATE IT ANYWAY?” I believe that would take more daring thinking than to find meat that was cooked in a naturally occurring fire and discovering that it tasted pretty good and was easier to digest.

In case anyone else is interested in this sort of thing, I recommend the book “Catching Fire: How Cooking Made Us Human” by Richard Wrangham. Be careful when ordering it. Make sure that you are ordering it by the entire title, or you might accidentally end up with the book “Catching Fire” from The Hunger Games Trilogy, which happened to me (but I still enjoyed both of them).

Reference:

Source: Mishra, K., Green, A., Burkard, J. et al. Valorization of cocoa pod side streams improves nutritional and sustainability aspects of chocolate. Nat Food 5, 423-432 (2024).